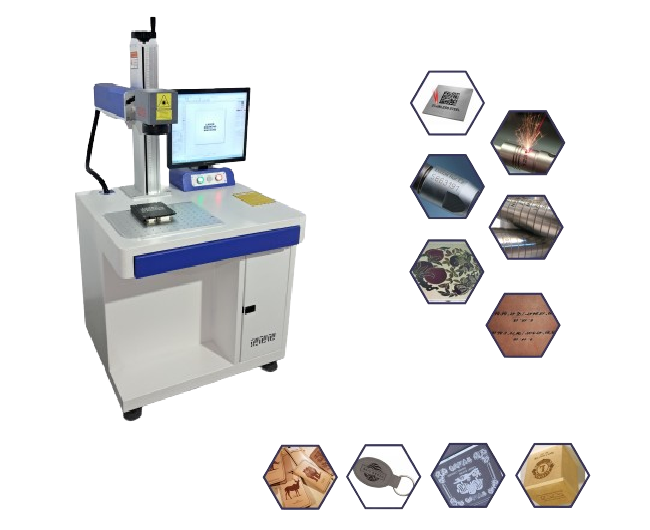

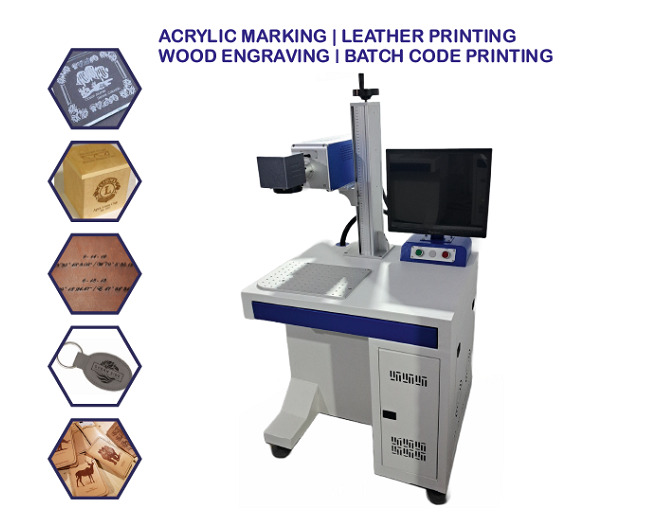

Wood Laser Marking Machine

Andaj AUTOMATION is a manufacturer of various types of laser engraving and marking equipment. We manufacture CO2 and UV laser marking machines. Our model AACLM-30W is a Wood Laser Marking Machine, which is ideal for marking wooden and other non-metallic components.

In addition to this, it offers advanced precision, making it suitable for intricate designs and applications.

Technical Specifications

The Wood Laser Marking Machine is engineered for precision and versatility, making it an excellent choice for various applications. Firstly, it utilizes a carbon dioxide (CO2) laser with a power output of 30 Watts, ensuring effective marking on non-metallic materials.

Moreover, it operates at a wavelength of 10.6 micrometers (µm), which is ideal for producing high-quality results. In addition, the machine boasts a marking speed of up to 700 mm/sec, enabling high-volume production without sacrificing quality.

Specification

| Laser Type | CO2 |

|---|---|

| Usage/Application | Wooden, Leather, Non Metal Marking |

| Marking Depth | 0.1 mm |

| Offering Laser | Leather |

| Capacity | CO2 Laser |

| Power | 30W |

| Voltage | 230V AC Power Supply |

| Automation Grade | Automatic |

| Marking Speed | 8000 mm/s |

Performance and Versatility

Firstly, it delivers consistent and high-quality markings, ensuring that every product meets stringent quality standards. Moreover, its ability to mark on a wide range of materials, including wood, glass, leather, and certain plastics, makes it an invaluable tool for diverse industries.

The Main Components Of Wood Laser Marking Machine

This machine uses a carbon dioxide (CO2) laser to create permanent marks on a variety of materials. CO2 laser marking machine are known for their versatility, power, and ability to produce high-quality marks on a wide range of surfaces.

Therefore, they are widely used in industries such as manufacturing, electronics, medical devices, and packaging. Additionally, the machine’s adaptability makes it suitable for intricate designs and high-volume production environments.

CO2 lasers typically operate at a wavelength of 10.6 micrometers (µm), which is in the infrared spectrum. As a result, this wavelength is well-suited for marking and engraving various materials.

In particular, it is highly effective for non-metallic materials, providing excellent results.

The marks produced by CO2 lasers are clean, sharp, and have high contrast. Thus, they are ideal for applications that require high-quality, permanent markings, such as barcodes, logos, serial numbers, and other identification marks.

As a result, this machine delivers excellent results for high-precision projects.

CO2 lasers can mark a broad range of materials, including wood, paper, leather, glass, ceramics, and many types of plastics and organic materials.

Moreover, they are effective for marking coated metals and some types of rubber. Thus, the machine offers broad material compatibility for various industries, increasing its utility.

CO2 laser marking machine can mark at high speeds, making them suitable for high-volume production environments. Additionally, they offer a high level of efficiency, as they can mark materials with minimal energy consumption.

Therefore, this machine is an ideal choice for businesses aiming to optimize productivity and reduce costs.

Applications of the Wood Laser Marking Machine

Electronics

In electronics, UV lasers mark circuit boards, semiconductors, and electronic components. Furthermore, they provide precise and durable markings essential for electronic devices. Consequently, they are widely used across the electronics industry.

Medical Devices

Moreover, in the medical field, they engrave medical instruments and implants. Additionally, this ensures that medical devices meet regulatory standards and traceability requirements, which are crucial for patient safety.

Consumer Goods

Personalization and branding on products like smartphones, watches, and jewelry. In addition, this provides unique identification for consumer goods, enhancing brand recognition and consumer appeal.

Packaging

Marking of date codes, batch numbers, and other information on packaging materials. As a result, this technology supports accurate and efficient packaging processes, helping businesses maintain product traceability.