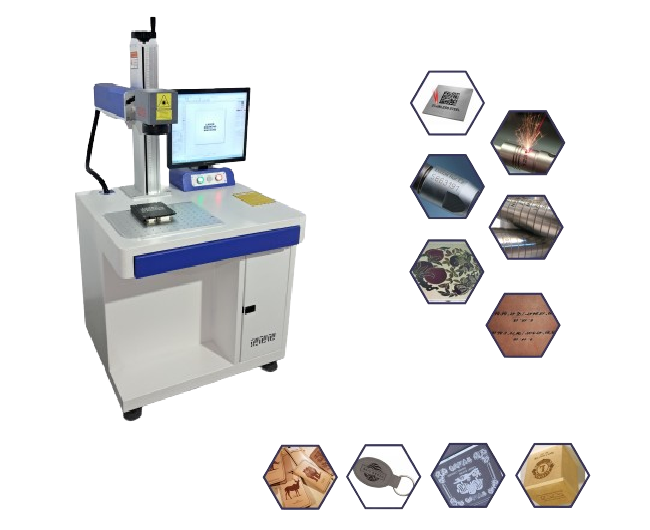

Utensil Laser Marking Machine

Andaj Automation manufactures the Utensil Laser Marking Machine with MAX, Raycus, and JPT Laser Sources. Moreover, laser marking employs a focused light beam to etch permanent marks on various surfaces.

Product Brochure

Specification

| Model | LM100 |

|---|---|

| Laser Source Power | 100W |

| Laser Source Brand | MAX/RAYCUS/IPG |

| Etching Material | Metallic ( MS, SS, Aluminium etc .. ) |

| Application | Marking & Engraving on Metal |

| Max Marking Speed | 10000 mm/s |

| Laser Type | Fiber Laser Source |

| Marking Depth | up to 0.8 mm |

| Marking Area | 300*300mm |

| Laser Wavelength | 1064nm |

Watch Utensil Laser Marking Machine

Key Applications of Utensil Laser Marking Machine

Versatility of Laser Types

This technique offers great versatility, as it utilizes different types of lasers such as Fiber, pulsed, continuous wave, green, and UV—each suited for specific materials. For instance, Fiber lasers excel at marking metals, whereas CO2 lasers work best for non-metals.

In addition, UV lasers create fluorescent marks on materials with low heat tolerance, like soft plastics. Furthermore, MOPA (Master Oscillator Power Amplifier) lasers allow color marking on stainless steel and black marking on anodized aluminium, which adds even more flexibility.

Product Portfolio

The Utensil Laser Marking Machine serves various industries, offering the ability to create permanent, high-quality marks on different materials. Additionally, you can explore our product portfolio on our web store: www.lasermarkingmachineindia.in.

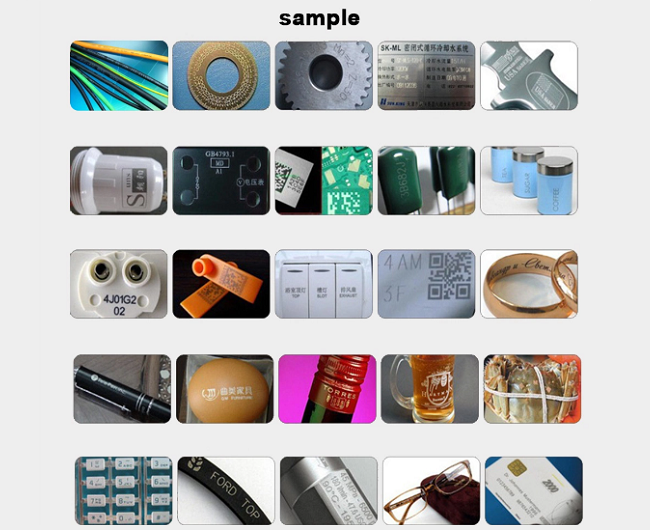

Applications Across Industries

Specifically, the Utensil laser marking machine engraves serial numbers, barcodes, and logos on automotive parts, tools, and machinery. It ensures traceability and authenticity throughout the supply chain.

Moreover, laser marking is crucial for identifying medical instruments and implants with biocompatible and sterilizable markings. This ensures compliance with regulatory requirements for traceability and patient safety.

In addition, companies within the consumer goods sector use laser marking for product branding, packaging, and marking consumer electronics, jewellery, and other items where both aesthetics and durability are important.

Meanwhile, the pharmaceutical industry uses laser marking to mark pills, capsules, and packaging with dosage information, lot numbers, and expiration dates, ensuring patient safety and regulatory compliance.

Additionally, laser marking engraves intricate designs, logos, and personalization on jewellery and luxury items, giving them a high-end finish that remains permanent and tamper-resistant.

In the food and beverage industry, laser marking is an excellent solution for marking expiration dates, batch codes, and other important information on food packaging. This process eliminates the risk of ink or toner contamination.

Furthermore, aerospace and defence industries rely on laser marking to imprint identification codes, serial numbers, and other crucial information on parts that must endure harsh environmental conditions.

Similarly, in the electronics industry, laser marking is applied to circuit boards, semiconductors, and electronic components, creating precise, small-scale markings that resist wear and chemicals.

Moreover, laser marking is ideal for identifying building materials such as pipes, valves, and fasteners with information that resists weathering and corrosion.

In research and development, laser marking is used to label prototypes, sample identifiers, and experimental equipment where precision and durability are essential.