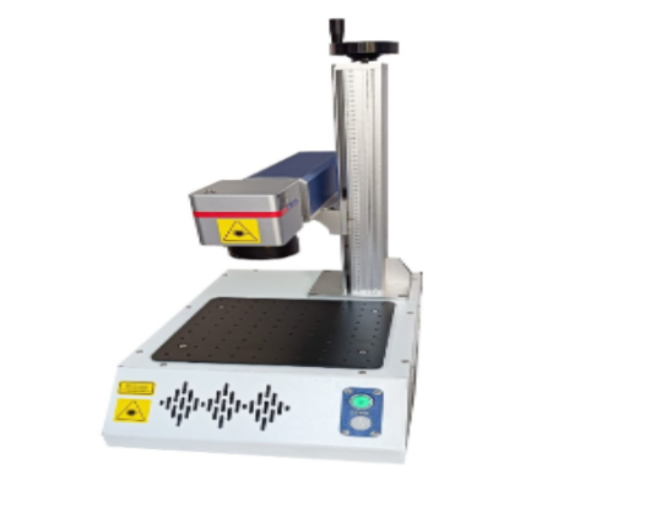

Compact Laser Rotary Marking Machine

Andaj Automation’s Compact Laser Rotary Marking Machine is perfect for engraving cylindrical objects such as bottles, glasses, and pens, offering versatility across industries like automotive, medical, and more.

Specification

| Marking Speed Capacity | 10000 mm/s |

|---|---|

| Usage/Application | Metal Marking |

| Laser Type | Fiber Laser |

| Marking Depth | up to 3mm |

| Offering Laser | Cables, CO2, Lldpe Drip Lateral, Hdpe Pipes |

| Automation Grade | Automatic |

| Power | 20W to 100W Laser Source |

| Voltage | 230V AC |

| Marking Area | 400*400 mm |

| Laser Wavelength | 1064nm |

Key Applications of Compact Laser Rotary Marking Machine

Versatility of Laser Types

Furthermore, this technique offers great versatility by utilizing different types of lasers such as Fiber, pulsed, continuous wave, green, and UV—each designed for specific materials. For example, Fiber lasers mark metals effectively, whereas CO2 lasers are more suitable for non-metals.

Product Portfolio

The Compact Laser Rotary Marking Machine offers the flexibility to mark various materials, ensuring high-quality results in industries ranging from food and beverage to electronics.

In addition to this, UV lasers create fluorescent marks on materials with low heat tolerance, like soft plastics. Moreover, MOPA (Master Oscillator Power Amplifier) lasers allow users to mark stainless steel with colors and anodized aluminium with black marks, adding significant flexibility.

Consequently, the Bearing Laser Marking Machine serves a variety of industries and enables users to create permanent, high-quality marks on different materials. Additionally, you can explore our product portfolio on our web store: www.lasermarkingmachineindia.in.

Applications Across Industries

Moreover, laser marking benefits a wide range of industries because it creates permanent, high-quality marks on various materials. Some key applications include:

Manufacturers use laser marking to engrave serial numbers, barcodes, and logos on automotive parts, tools, and machinery. Specifically, it ensures traceability and authenticity throughout the supply chain. As a result, companies can easily track their products.

Additionally, medical device manufacturers engrave instruments and implants with biocompatible and sterilizable markings, ensuring they comply with regulatory requirements for traceability and patient safety. Therefore, the healthcare industry benefits from this method.

In the consumer goods sector, manufacturers use laser marking for product branding, packaging, and engraving of consumer electronics, jewellery, and other items where aesthetics and durability are important. As a result, these products maintain a premium look while ensuring the marks last.

Meanwhile, pharmaceutical companies mark pills, capsules, and packaging with dosage information, lot numbers, and expiration dates, ensuring patient safety and regulatory compliance. Furthermore, the permanent markings assist in maintaining accuracy throughout distribution.

Moreover, jewellers and luxury goods manufacturers engrave intricate designs, logos, and personalization on jewellery and luxury items, creating a high-end finish that is permanent and tamper-resistant. Thus, customers enjoy durable and aesthetically pleasing products.

In the electronics industry, companies mark circuit boards, semiconductors, and electronic components with precise and small-scale engravings that resist wear and chemicals. Thus, these markings ensure durability and reliability.

For aerospace and defence applications, companies mark parts with identification codes, serial numbers, and other critical information that withstand harsh environmental conditions. Thus, the process ensures the longevity and readability of the markings in extreme environments.

In the food and beverage industry, companies use laser marking to print expiration dates, batch codes, and other information on packaging materials without the risk of ink or toner contaminating the product. Consequently, this method ensures both safety and cleanliness.

Additionally, manufacturers apply laser marking to building materials such as pipes, valves, and fasteners, ensuring the identification information resists weathering and corrosion. As a result, these markings remain readable even in harsh conditions.