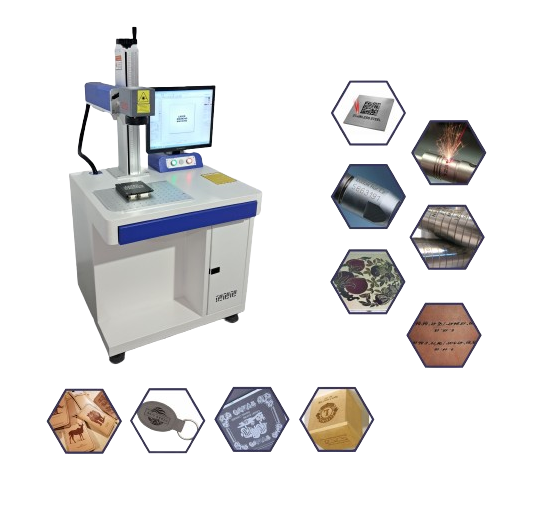

CO2 LASER MARKING MACHINE

Andaj AUTOMATION manufactures various types of laser engraving and marking equipment. Specifically, the company uses CO2 laser marking machine to create permanent marks on a variety of materials.

CO2 lasers offer versatility, power, and the ability to produce high-quality marks on a wide range of surfaces. Consequently, industries such as manufacturing, electronics, medical devices, and packaging widely use CO2 laser marking machine. Furthermore, their adaptability makes them suitable for different applications, which enhances their value in various industrial sectors

APPLICATION OF CO2 LASER MARKING MACHINE

Main Features of CO2 Laser Marking Machine

Wavelength

CO2 lasers typically operate at a wavelength of 10.6 micrometers (µm), which is in the infrared spectrum. This specific wavelength is well-suited for marking and engraving various materials. Additionally, this wavelength allows for precise and consistent marking across different surfaces.

Mark Quality

The marks produced by CO2 lasers are clean, sharp, and have high contrast. Consequently, this makes them ideal for applications that require high-quality, permanent markings, such as barcodes, logos, serial numbers, and other identification marks. Furthermore, the high contrast enhances the readability and durability of the marks.

Material Compatibility

CO2 lasers can mark a broad range of materials, including wood, paper, leather, glass, ceramics, and many types of plastics and organic materials. In addition, they are also effective for marking coated metals and some types of rubber. Therefore, their wide material compatibility makes them suitable for diverse applications.

Speed and Efficiency

CO2 lasers can mark at high speeds, making them suitable for high-volume production environments. Moreover, they have a high level of efficiency, as they can mark materials with minimal energy consumption. As a result, they contribute to cost savings and increased productivity in industrial settings.