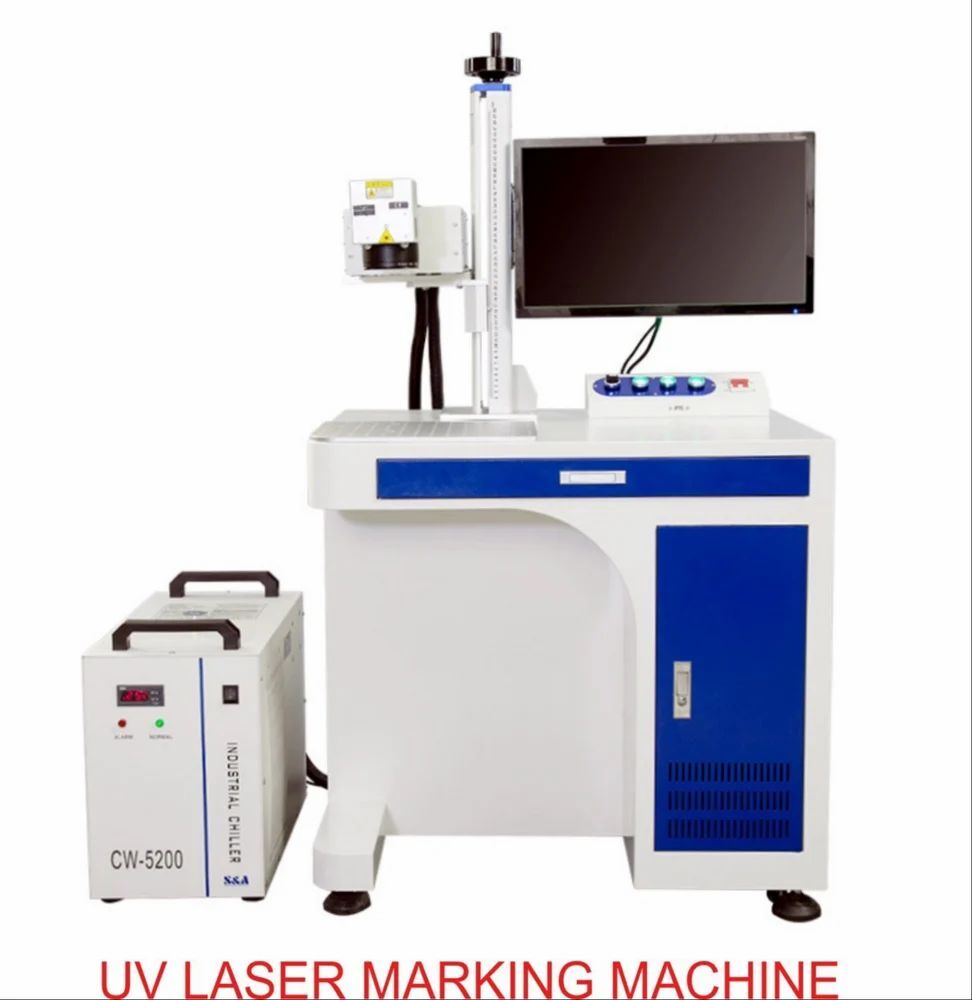

7w UV Laser Marking Machine

We manufacture UV Laser Marking machines in 3W, 5W, 7W, and 10W to meet various customer applications. Our UV laser marking machine uses an ultraviolet (UV) laser to create permanent marks on a variety of materials.

Additionally, it offers precise and high-quality marking solutions for several industries. Moreover, this advanced technology ensures both accuracy and consistency, which are crucial for meeting diverse marking needs.

Specification

| Offering Laser | Lldpe Drip Lateral |

|---|---|

| Marking Speed Capacity | W30000 mm/s |

| Marking Area | 400mm x 400mm |

| Automation Grade | Automatic |

| Application | Glass, Plastic, and non metal component marking |

| Cooling Mode | Water cooled |

| Water Chiller | Glass, Plastic, and non metal component marking |

| Marking Depth | 0.1mm |

| Laser Source Power | 3W |

| Voltage | 230V AC Supply |

Key Features of 7W UV Laser Marking Machine

The 7W UV Laser Marking Machine delivers high precision, speed, and fine details. Moreover, it excels in marking and engraving materials that traditional laser sources, such as glass, ceramics, and certain plastics, struggle to process.

When selecting a 7W UV Laser Marking Machine, consider factors like laser power, work area size, software and control systems, and the manufacturer’s support and reliability. In addition, implementing proper training and safety measures ensures the safe and effective use of the equipment.

Technical Specifications

Typically operating at a wavelength of around 355 nm (nanometers), these lasers fall within the ultraviolet light spectrum. This shorter wavelength therefore allows for finer details and higher resolution compared to longer-wavelength lasers like CO2 or fiber lasers. Additionally, this feature enhances the machine’s ability to perform precise marking tasks.

Capable of high-speed marking, this laser technology is ideal for high-volume production environments. Moreover, its efficiency ensures minimal energy consumption while delivering excellent performance. As a result, it helps reduce operational costs and improve productivity.

The non-contact nature of UV laser marking ensures that the material remains undamaged. As a result, it is ideal for delicate or brittle materials. In addition, this characteristic helps preserve the material’s original condition and extend its lifespan.

This type of laser marks a wide range of materials, including metals, plastics, glass, ceramics, and certain coated materials. Specifically, it excels in marking transparent and colored plastics without altering the material’s properties. Thus, it offers a broad range of applications across different industries.

It produces clean, sharp, and high-contrast marks. Thus, it is perfect for applications that require high-quality, permanent markings, such as barcodes, logos, and serial numbers. Furthermore, this quality is essential for maintaining product integrity and traceability.

Applications

Electronics

In electronics, UV lasers mark circuit boards, semiconductors, and electronic components. Furthermore, they provide precise and durable markings essential for electronic devices.

Medical Devices

Moreover, in the medical field, they engrave medical instruments and implants. Additionally, this ensures that medical devices meet regulatory standards and traceability requirements.

Automotive

Furthermore, in the automotive industry, UV lasers mark engine parts, tools, and accessories. As a result, they help improve part identification and quality control.

Aerospace

Lastly, in aerospace, they identify components and parts with durable markings. Consequently, this contributes to the safety and reliability of aerospace equipment.