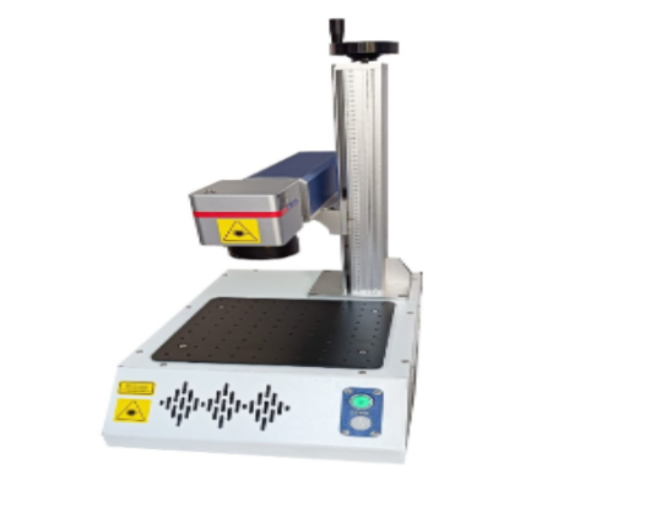

50w Compact Laser Marking Machine

Fiber lasers excel in marking metals, while CO2 lasers are optimal for non-metals. Moreover, the 50W Compact laser marking machine is highly versatile, offering UV lasers that are particularly useful for creating fluorescent marks on materials with low heat tolerance, such as soft plastics.

In addition, MOPA (Master Oscillator Power Amplifier) lasers offer flexibility; they allow for color marking on stainless steel and black marking on anodized aluminum.

Specification

| Laser Type | Fiber Laser |

|---|---|

| Laser Source | 50W |

| Marking Area | 400mm x 400mm |

| Material Compatibility | Stainless Steel |

| Automation Grade | Automatic |

| Usage/Application | Metal Laser Marking |

| Marking Depth | up to 1mm |

| Offering Laser | Metal marking, Cables |

| Marking Speed | 8000 mm/s |

| Marking Speed Capacity | 10000 mm/s |

Primary Types of the 50W Compact Laser Marking Machine

Fiber lasers, such as those in the 50W Compact Laser Marking Machine, excel in marking metals, while CO2 lasers are optimal for non-metals. UV lasers, particularly those in mini laser marking machines, are useful for creating fluorescent marks on materials with low heat tolerance, such as soft plastics. Additionally, MOPA (Master Oscillator Power Amplifier) lasers offer flexibility, allowing for color marking on stainless steel and black marking on anodized aluminum.

Laser marking, including with the 50W Compact Laser Marking Machine, utilizes several types of lasers, each with its own set of characteristics and material compatibility. Here are the primary types of lasers used for marking and the materials they are best suited for.

Applications of the 50W Compact Laser Marking Machine

Choosing the right laser depends on the material, desired marking quality, and application needs.

These lasers are highly efficient and produce a high-quality beam. As a result, they are ideal for marking metals such as steel, aluminum, and titanium. Additionally, they can mark certain types of plastics with speed and precision.

CO2 lasers work best on non-metallic materials like wood, paper, leather, and various plastics. They offer versatility, making them ideal for cutting, engraving, and marking applications.

MOPA lasers provide versatility in color marking on metals like stainless steel and black marking on anodized aluminum. They can adjust pulse duration and frequency to achieve different marking effects.

On the other hand, UV lasers, particularly those with a wavelength of 355 nm, are excellent for marking materials with low heat tolerance.

For instance, they work well on soft plastics, glass, and certain electronic components. As a result, they produce high-quality, fine markings without causing thermal damage to the material.

Green lasers, with a wavelength of 532 nm, offer a balance between the power of CO2 lasers and the precision of UV lasers. They are suitable for marking a range of materials, including metals, ceramics, and some plastics.

Pulsed lasers, including Fiber and CO2 types, handle applications requiring high peak power for marking or engraving. They are suitable for a variety of materials and can produce high-contrast marks.