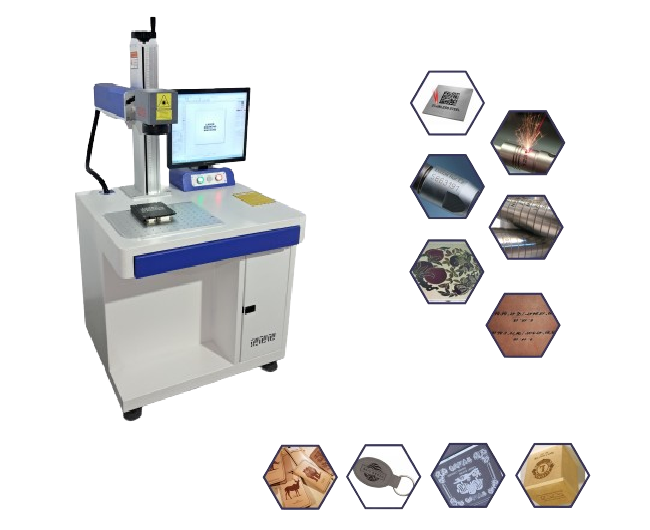

30w Fiber Laser Marking Machine

Andaj Automation manufactures the 30W Fiber Laser Marking Machine. This machine uses a focused light beam to permanently etch marks on various surfaces.

In fact, the technique offers incredible versatility, as it employs different types of lasers, such as Fiber, pulsed, continuous wave, green, and UV—each one suited for specific materials and applications.

Product Specification

Specification

| Model | LM30 |

|---|---|

| Laser Source Power | 30W |

| Laser Source Brand | MAX/RAYCUS/IPG |

| Etching Material | Metallic ( MS, SS, Aluminium etc .. ) |

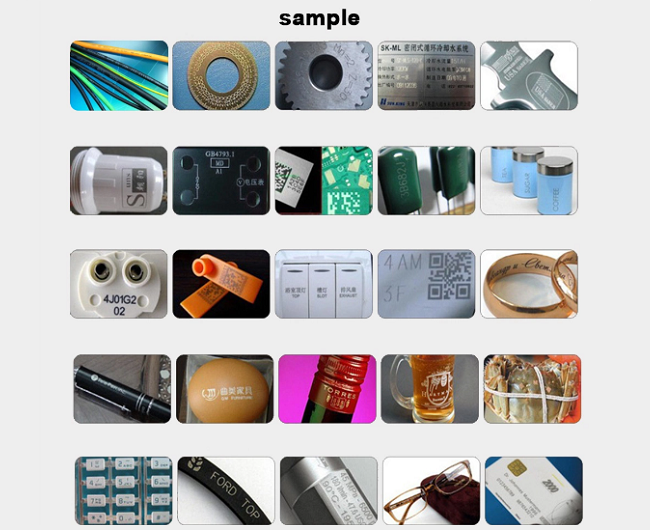

| Application | Marking & Engraving on Metal |

| Max Marking Speed | 10000 mm/s |

| Laser Type | Fiber Laser Source |

| Marking Depth | up to 0.8 mm |

| Marking Area | 300*300mm |

| Laser Wavelength | 1064nm |

Types of Laser Marking

Laser marking utilizes several types of lasers, including the 30W Fiber Laser Marking Machine, each with unique characteristics and compatibility with different materials.

Therefore, it is important to choose the right laser based on the material and the specific application requirements. As a result, each laser type offers distinct advantages. Below are the different types of lasers commonly used in laser marking:

Fiber lasers effectively mark metals. Consequently, they offer high precision and speed, making them a popular choice for industrial applications.

UV lasers excel at marking materials with low heat tolerance, such as soft plastics. Additionally, they create fluorescent marks without damaging the material. As a result, they are commonly used for marking sensitive materials.

Pulsed lasers, including both Fiber and CO2 varieties, deliver high peak power, making them ideal for marking or engraving a wide range of materials. Furthermore, their versatility allows them to produce high-contrast marks.

Green lasers perform exceptionally well when marking highly reflective materials. In fact, their wavelength suits sensitive materials that require lower heat, providing great precision and clarity.

MOPA lasers offer flexibility, allowing you to mark in color on stainless steel and create black marks on anodized aluminum.

Consequently, this feature makes them perfect for specialized marking tasks.

CW lasers emit a continuous beam of light, often used for cutting and welding. However, you can also use them for marking specific materials, especially when high heat is necessary.

Therefore, they are versatile in both cutting and marking applications.